During December of 2023, a General Cargo Ship was inspected in Ravenna, Italy (Port UNLOCODE ITRAV) resulting to a PSCI report with 15 Deficiencies (including ISM-15150). Given the increased number of deficiencies recorded, the scope of the case study is to illuminate the case, root causes and lessons to be learned, reports Safety4sea.

Ship background & PSCI Eligibility

The 12 years old ship (YoB 2010, Built in China) was assessed with a PSC Inspection Window Open given the Risk Profile of the ship and the Manager in the MoU area. The ship was eligible for inspection, as she had an inspection window opened for inspection in Paris MoU since 3/10/2023.

The ship’s Manager (DOC holder) manages a fleet of 12 General cargo Ships.

The ship’s PSC history during Last 36 Months included 7 inspections as below:

| Date (mm/yyyy) |

Port | Country | MOU | PSCI Eligibility | Detention | # of Defs |

| 1/12/2023 | Ravenna | Italy | Paris | Yes | No | 15 |

| 3/10/2022 | Mombasa | Kenya | Indian Ocean | Yes | No | 0 |

| 6/8/2022 | Klaipeda | Lithuania | Paris | No | No | 2 |

| 28/3/2022 | New Orleans | USA | USCG | Yes | No | 1 |

| 22/11/2021 | Mersin | Turkey | Mediterranean | Yes | No | 1 |

| 8/11/2021 | Novorossiysk | Russia | Black Sea | Yes | No | 0 |

| 30/9/2021 | Ortona | Italy | Paris | Yes | No | 0 |

| 15/6/2021 | Cienfuegos | Cuba | Vina Del Mar | Yes | No | 0 |

The ship had been inspected in Paris MoU for the last time in Klaipeda during August 2022 with 2 deficiencies. The last inspection in Italy was back in 2021 in Ortona with zero deficiencies. As mentioned above, the Inspection Window was opened for inspection and Managing Company should have been prepared for expanded inspection on the ship.

Manager Background (prior the detention)

Manager’s PSC record for the Last 36M (Oct 20-Nov 23) included 31 inspections resulting in 14 deficiencies and 0 detentions. The inspections were mostly conducted by USCG (8), Paris MoU (5), Tokyo MoU (5) & Vina Del Mar (5). Manager’s Deficiency per inspection (DPI) was 0.48 (while the Global Benchmark for similar aged and type ships is 1.48) and the detention ratio (DER) was 0% (while the Global Benchmark for similar fleet is 2.7%).

Port Background

In Ravenna (Port UNLOCODE ITRAV) for the period of the last 36 months, (prior this inspection) there were 133 inspections on General cargo Ships which resulted in 30 detentions. Port’s detention Rate (DER) is 22.5% which is almost more than 5 times higher than the Global Average for ports inspecting General cargo Ships (4.74%).

Port’s Deficiency per Inspection (DPI) for the last 36M was 11.54, significant higher than Global Average for ports inspecting General cargo Ships (3.03), approximately 4 times more.

Above statistics show that Ravenna is a very challenging port for general cargo ships, with PSC KPIs (related to detentions and deficiencies), highly above the Global Benchmarking, showing that this is a strict and very challenging port for general cargo ships.

Port Call Risk Assessment (POCRA)

The PSCI has been analyzed with the Port Call Risk Assessment (POCRA) Risk Assessment Tool of the RISK4SEA Platform with the following outcome:

PSC Inspection Probability

The ship’s prior inspection in Paris MoU was back in August 2022, providing a window opened date 4/8/2023, with a soft opening period of 2 months as Priority II (PSCI may be expected), until 4/10/2023 after which the ship became Priority I (PSCI should be expected). It is clear that the ship was eligible for PSCI. Additionally, the previous PSCI in Paris MoU (Klaipeda inspection), had resulted to 2 deficiencies (which should be checked for rectification). The 2 deficiencies were associated with Oil Record Book and Auxiliary Engines.

The ship inspection rate (SIR) for the unique ships for the last 12M in Ravenna Port was 20%, meaning that 2 out of 10 unique General cargo called in Ravenna were inspected.

As the ship had an open Inspection window open date and the PSC history of ship and manager was well known and assessed by the local PSC authorities, the inspection probability was assessed as CERTAIN.

PSC inspection Severity

Ship related factors marked several risks (Yellow Flag) as follows:

- Ship Deficiency Profile vs Port Top 20 Deficiency Codes

- Ship Age Risk (>12 years old)

Manager PSC history within MoU was assessed as medium risked. Some parameters were Red Flag, specifically:

- Manager DPI in Port – Manager had no experience for the specific port as no inspection conducted during L36M

- Manager Deficiency Profile vs Port Top 20 Deficiency Codes (10 common deficiency codes)

Port related factors were assessed to be Medium risk (Red Flag) as port’s KPI were highly above Global Average.

Overall POCRA Assessment

Taking into consideration the above Inspection Probability and Inspection Severity, the overall POCRA assessment was that the call risk was High.

This should be an alert factor for the preparation of the ship.

PSC Inspection Result

Ship called Ravenna and PSCO Officers boarded for inspection and to check the ship’s safety status and condition. The result of the PSC inspection was 15 deficiencies (non detainable). As it is expected in such situations, the code 15150- ISM Code was marked to engage Manager to verification of ISM Implementation on board through an additional ISM Audit.

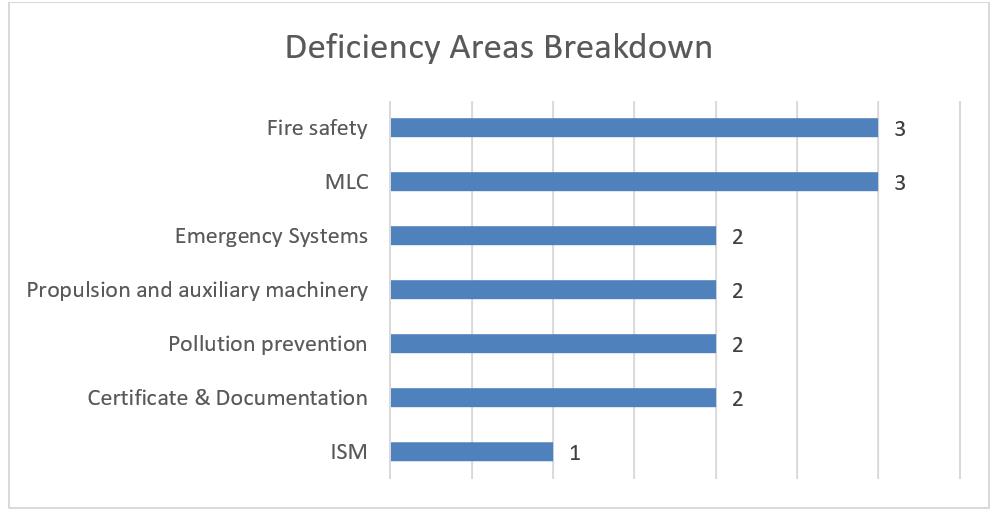

The breakdown of the Deficiency Areas that the ship found to be deficient were:

Root Causes

Out of approximately 5k ships that are being detained every 36 months, almost 90% of these ships have no other detention in the 36 months prior to that detention. This is a strong and clear indication that any ship may be detained or have high number of deficiencies if not properly prepared. Research has provided evidence that the ships are being detained for the following key reasons:

- Inadequate identification that the ship will be inspected: It is evident in this case by the end result.

- Inadequate Preparation of the crew and the ship as a hardware: Numerous deficiencies in the areas where weekly inspections are due (FFA, LSA, Cargo Operations) are a testimony to that.

- Inadequate Maintenance: All deficiencies were related to proper maintenance practices.

Here all above reasons have been observed leading into the obvious result.

POCRA preparation checklist

If the vessel had used the POCRA preparation checklist, the findings may have been resulted differently. The POCRA checklist in Ravenna for the specific ship generates a specific checklist including 60 items analyzed in detail. This checklist includes all 15 findings of the inspection under review. If the vessel had prepared properly, all of the items marked on PSC inspection would be avoided and ship/ Manager would not have been further targeted within Paris MoU.

Lessons to be Learned

There is a number of lessons to be learned out of this case as follows:

- Ship has an established problem in Pollution Prevention as 2 deficiencies were in this area, plus one for SOPEP. Additionally, the previous Deficiencies in the same MoU were also Pollution Prevention related.

- Crew training also shows to be deficient as Abandon Ship drill and familiarity with emergency systems were marked by PSCO.

- Fire safety should also be reviewed as per PSCO findings.

- Extreme Caution should be exercised on the handling of the ISM Codes 15xxx. It is highly recommended that an additional audit onboard the ship is carried out to verify SMS implementation (regardless if this is asked by PSCO or not).

Did you subscribe to our daily newsletter?

It’s Free! Click here to Subscribe!

Source: Safety4sea