Mitsui O.S.K. Lines, Ltd. announced that it has reached an agreement for joint development of the next-generation engine failure sign diagnosis application, in partnership with ClassNK, IHI Power Systems, and Mitsui E&S Machinery, says a press release published in their website.

Joint partnership

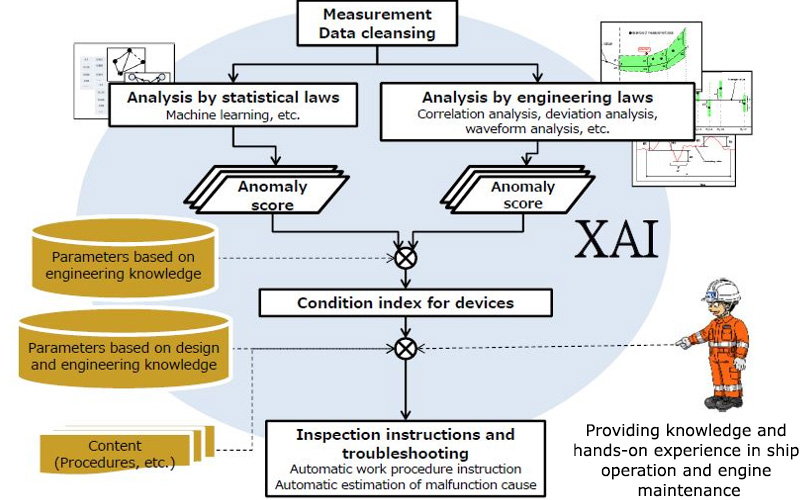

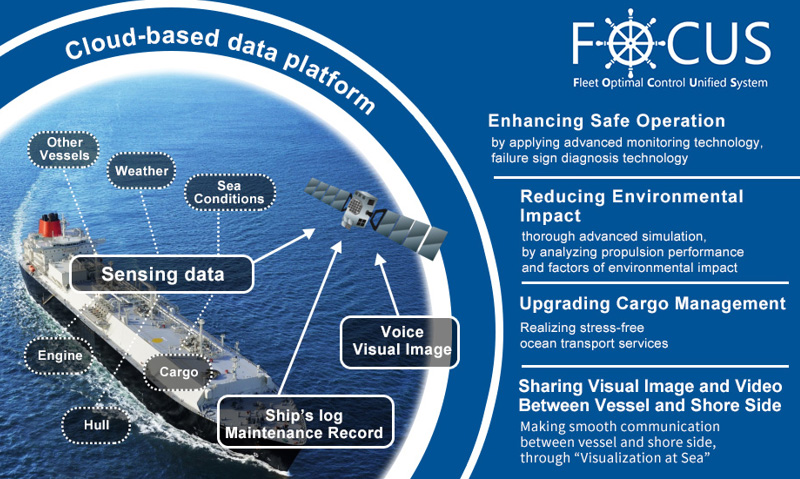

The four companies are looking to develop the application by fusing ClassNK’s “CMAXS LC-A/e-GICSX“(CMAXS) and MOL’s FOCUS “Fleet Optimal Control Unified System“, which is intended to enhance safe operation and reduce environmental impact through advanced information and communications technology (ICT). The four companies will unite to develop a system called “Fleet Guardian,“ which encompasses a new implementation of Explainable AI (XAI), the most advanced human-friendly artificial intelligence.

Eliminates vessel downtime

Fleet Guardian is expected to eliminate vessel downtime and further improve the level of safe operation by enabling crewmembers and shoreside staff to share information on a vessel’s engine status in a timely manner.

[Schemes in the joint study that each company will emphasize]

| MOL | NKCS | Mitsui E&S Machinery | IHI Power Systems |

|---|---|---|---|

| Provide feedback related to knowledge and hands-on experience in ship operation and engine maintenance | Improve the CMAXS failure sign diagnosis system based on the provided feedback information. Newly implement the interface with the latest human-friendly XAI. |

||

Improve accuracy and speed

The goal of the Fleet Guardian project is to establish a system that will improve accuracy and speed of failure sign diagnosis by continually adjusting the results of automatic (sign) diagnosis and actual operational status while incorporating functions that will contribute to seafarer training and education. The project team members plan to design CMAXS in a way that makes it easier for seafarers to understand automatic diagnosis results, and helps them gain a deeper knowledge and understanding of the engine every time they use it.

The project aims at zero downtime due to engine failure by establishing a system jointly operated by users and engine manufacturers, by continually improving the accuracy of the system itself and by providing seafarers a more comprehensive understanding of changes in engine status.

Smart ship project

MOL has moved ahead with advanced support of safe operation and reduction of its environmental impact, as set out in the “ISHIN NEXT – MOL SMART SHIP PROJECT“ which started in November 2016 and aims to become customers’ first choice as a logistics partner by applying ICT technology to improve service quality and efficiency.

Did you subscribe to our daily newsletter?

It’s Free! Click here to Subscribe!

Source: MOL