Short deliveries are a real issue in bunkering and Ascenz Marorka is the first to introduce a digital monitoring solution for mass flow meters, reports JSPFA.

Introduction

In 2022, an independent study conducted by the consulting company BLUE Insight revealed that ‘short bunker deliveries’ remain prevalent in Rotterdam and Fujairah – with the issue likely to be exacerbated by the prospect of new, more expensive low carbon fuels entering the market. The study concluded that about 3% of the bunkers in the second largest port in the world recorded as delivered were never actually pumped on the ship. Also, 80-90% of the survey respondents recognize the issues outlined (i.e. bunker quantity problems).

Ascenz Marorka was the first technology company to introduce in Singapore (and in the world) a digital bunkering monitoring solution using mass flow meters to improve the accuracy of the bunkering measurement.

Advanced bunkering monitoring

Bunkering monitoring often takes place at the point of custody transfer, where the transferred quantity can be confidently quantified according to the purchase contract. Usually, mass flow meters are used to ensure quantity and quality of the flow transfer. The digital monitoring of the entire bunkering process with real-time data collection and artificial intelligence coupled with operational experience can limit the errors, negligence and the malpractices. In this process, Ascenz Marorka acts as the third party of confidence to increase transparency and accountability of the commercial transaction.

In fact, malpractice can occur in many ways, such as cappuccino bunkers with excessive flow aeration, tampering with pipelines and seals, interference with the meters using magnets, contamination of fuel with water, use of uncertified or faulty flow meters…

At the opposite of all the other types of flow meters, the mass flow meters are unaffected by the flow profiles. For example, the concerns arising from changing temperature, viscosity, and pressure conditions are eliminated to deliver higher accuracy and reliability. With no moving parts, the mass flow meters are adapted for the harshest marine conditions. Flowmet® mass flow meters (an Ascenz Marorka brand) are perfectly designed for reliable and accurate measurements under challenging conditions.

In addition to technology, the entire system performance is guaranteed by proper meters selection and installation, acceptance tests and extensive checks of mechanical, software, electrical and operational security. For example, equipment are sealed against unauthorized adjustment, tampering or dismantling; software on-board are protected against any unauthorized change, data collected during the bunkering process is stored securely onboard and in the cloud for many years to be vizualised or to support claims if need be, critical alarms are activated in real-time if there is a suspicious behavior…

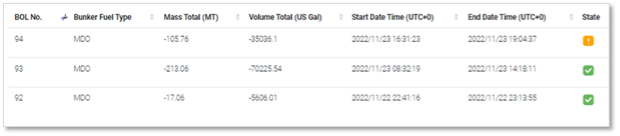

The system provides a full view of bunkering activities including key parameters such as mass flow rate, density, temperature and drive gain

The Smart Bunkering feature is more than a mere visualisation of the situation. It offers a valuable analysis throughout the bunkering process using state-of-the-art artificial intelligence.

Did you subscribe to our newsletter?

It’s free! Click here to subscribe!

Source: JPSFA