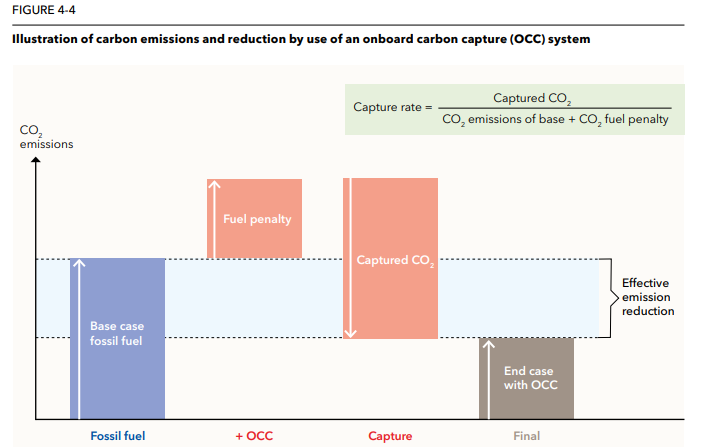

- Onboard carbon capture (OCC) can be a technically feasible option for reducing emissions and could be commercially attractive if the right regulatory and market drivers are in place.

- A new DNV white paper provides a comprehensive overview of all key considerations around OCC.

DNV has published a white paper which aims to offer guidance to shipowners, technology providers, and other stakeholders on central matters related to onboard carbon capture.

The potential of onboard carbon capture in shipping

According to DNV’s “The potential of onboard carbon capture in shipping” paper, onboard carbon capture systems will depend on a developed infrastructure for wider carbon capture, utilization, and storage (CCUS), as such capture will be the starting point of a long logistics chain.

Step 1 – Onboard capture

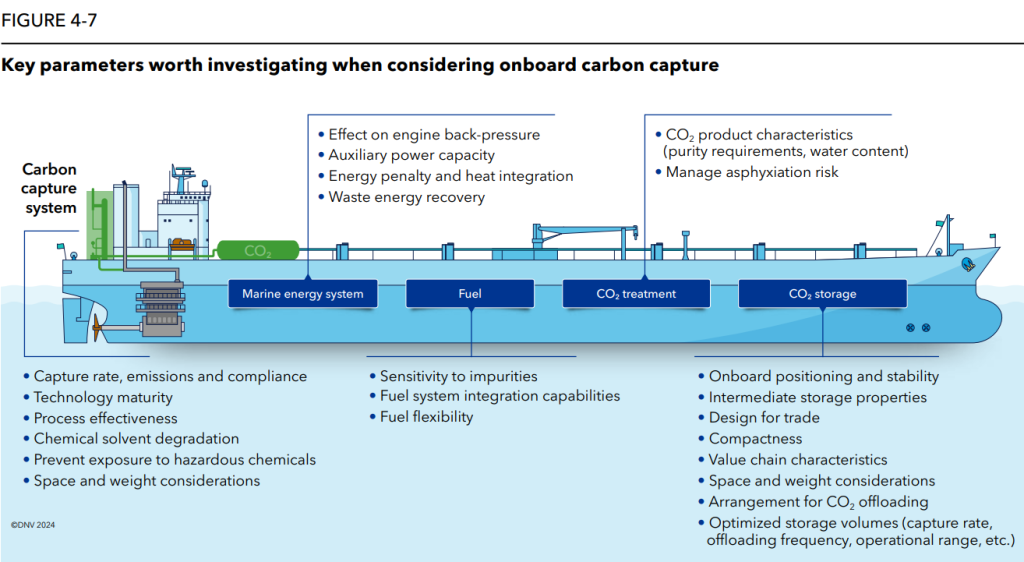

The ship will require a system to capture, remove, and process the CO2 to a state suitable for onboard storage. The captured carbon can be in various states, depending on the capture method: compressed gas, liquid, or solid (bonded in a mineral).

Step 2 – Onboard storage

The captured carbon is temporarily stored on board before being offloaded. Depending on the CO2 state, different properties and containment systems are needed. In the case of liquid, the CO2 product may be stored in IGC Type C tanks, following IGF code requirements, and the CCUS value chain properties.

Step 3 – Offloading

Periodically, the ship will need to get rid of the captured carbon, either at the end of a voyage, or by making additional port calls or offloading to CO2-carrying vessels. The offloading frequency depends on the trade and the availability of disposal facilities (e.g., CO2 terminals, floating collecting hubs, and CO2 receival vessels).

Step 4 – Transportation

After offloading, the CO2 is transported to CO2 reception facilities. In general, the CO2 can be transported by ship and pipelines (but also trucks and trains). The facilities will be important nodes of the value chain, as further processing may be needed to prepare and condition the CO2 stream to be compatible with the downstream CCUS value chain.

Step 5 – Permanent storage or utilization

The value chain ends with either permanent storage (sequestration) as waste or utilization. As waste, the captured CO2 is permanently stored in deep underground geological formations.

Connecting onboard carbon capture to the CCUS value chain

The uptake of onboard carbon capture technologies will need to be linked to the development of the wider CCUS value chain. Large onshore CO2 emitters, such as industries that consume fossil energy or produce CO2 as a by-product of their production processes (e.g., steel, cement, and fertilizers), drive the need for developing this logistics chain, as the volume from single onshore emitters is much larger than from an individual ship.

Successful downstream integration of onboard captured carbon in the CCUS value chain depends on the ability to offload the CO2 at convenient locations and then connect to carbon storage or utilization locations, DNV notes.

Did you Subscribe to our daily newsletter?

It’s Free! Click here to Subscribe!

Source: DNV