On 13th of February of 2023 a General Cargo Ship Flying the Panama Flag, inspected in Nakhodka, Russia (Port UNLOCODE RUNEV) resulting in a detention with 40 Deficiencies, reports Safety4sea.

Ship background

The 23 years old ship (YoB 2000, Built in Shin Kochi Jyuko – Kochi, Japan) was assessed with an Inspection Window Open given the Risk Profile of the ship and the Manager in the MoU area.

The ship’s manager was based in Ho Chi Minh City, Vietnam, managing a total of 3 General Cargo ships. It is worth mentioning that the ship has been classed in the same IACS classification society since 2000.

The ship’s PSC history during Last 36 Months included 15 inspections in Philippines, Russia, Papua, Indonesia, Malyasia and Bangladesh, all in Tokyo and Indian Ocean MoU PSC regions.

This was the 73rd inspection of the ship under the same manager (since 2008). Ship also had detained in the past as follows:

- Vladivostok, Russia – 26/02/2020 – with 30 deficiencies (within 36M period)

- Vanimo, Russia – 26/03/2019 – with 17 deficiencies

- Nigata, Japan -12/09/20124 – with 8 deficiencies

Manager Background

Manager’s PSC record the Last 5 years (2018-2022) was 69 inspections resulting in 368 deficiencies and 5 detentions. All inspections conducted in Tokyo and Indian Ocean MoU. Manager’s Deficiency per inspection (DPI) is 5.77 (while the Global Benchmark for similar aged general cargo ships is 4.08) and the detention ratio (DER) is 7.25% (while the Global Benchmark for similar aged General Cargo ships is 5.60%).

Manager’s Profile in Tokyo MoU was calculated to be Very based on Last 36M PSC History in MoU.

Port Background

In (Port UNLOCODE RUNEV) for the period of the last 36 months, (prior this inspection) there were 494 inspections on general cargoes resulted 48 detentions. Port’s detention Rate (DER) is 9.72% which is the triple than Global Average for ports inspecting General Cargo Ships (3.65%)

Port’s Deficiency per Inspection (DPI) the last 36M is 4.27, almost double from Global Average for ports inspecting General Cargo ships (2.70).

Port Call Risk Assessment (POCRA)

The PSCI has been analysed with the Port Call Risk Assessment (POCRA) Risk Assessment Tool of the RISK4SEA Platform with the following outcome

PSC Inspection Probability

The ship’s prior inspection in Tokyo MoU was 10/06/2022, however as the ship was rated HRS and the Manager’s performance in MoU was rated as very low the Inspection window opened date was opened since August 2022. Ship the Last 36M had a detention in Tokyo MoU and in same Country (Russia). The ship inspection ratio (SIR) the last 12M was 48%, meaning that 5 out of 10 unique ships conducted call in Nakhodka were inspected.

As the ship had an open Inspection window open date and and the PSC history of ship and manager was well known and assessed by the local PSC authorities, the inspection probability was assessed as CERTAIN

PSC inspection Severity

Ship related factors were mostly high risk (red flagged) due to previous ship’s PSC history within MoU and ship age (23 years old)

Manager PSC history within MoU was also assessed as high risked. Several parameters were red flag, specifically,

- Manager Inspections in MoU/PSC Regime

- Manager DPI in Port

- Ship DPI with the Manager

- Manager Detention Profile vs Port Detainable Items

- Manager Deficiency Profile vs Port Top 20 Deficiency Codes

Port related factors were also assessed to be high risk (red flag) as below factors are higher than relevant ports worldwide for General Cargo Ships’ inspections.

- Port Deficiency Codes Spread

- Port Detention Ratio – L12M

- Port Deficiency Per Inspection – L12M

Overall POCRA Assessment

Taking into consideration the above Inspection Probability and Inspection Severity the overall POCRA assessment was that the call risk was Critical.

For a ship and a manager with such a previous history in the MoU this should be an alert factor for preparation.

PSC Inspection Result

The result of the PSC inspection was a list of 40 deficiencies for different aspects of technical and structural conditions and safety of navigation.

As is expected in such situations the code 15150 – ISM was marked (as detainable) in order to lead to additional onboard audit to verify the SMS implementation status on board.

Apart this code the vessel was detained for 12deficiencies and 7 different deficiency areas:

- 2 deficiencies related to Fire Safety (07199 – Other (fire safety), 07126 – Oil accumulation in engine room)

- 3 deficiencies related to Safety of Navigation (10111 – Charts, 10199 – Other (navigation), 10116 – Nautical publications).

- 2 deficiencies related to Life Saving Appliances (11101-Lifeboats, 11134 – Operation of Life Saving Appliances)

- 2 deficiencies related to Propulsion and auxiliary machinery (13102 – Auxiliary engine 2 findings)

- 1 deficiency related to Radio Communications (05105 – MF/HF Radio installation)

- 1 deficiency related to Pollution Prevention (14811 – Ballast Water Management System)

- 11 deficiencies related to MLC working conditions (18410 – Gas instruments)

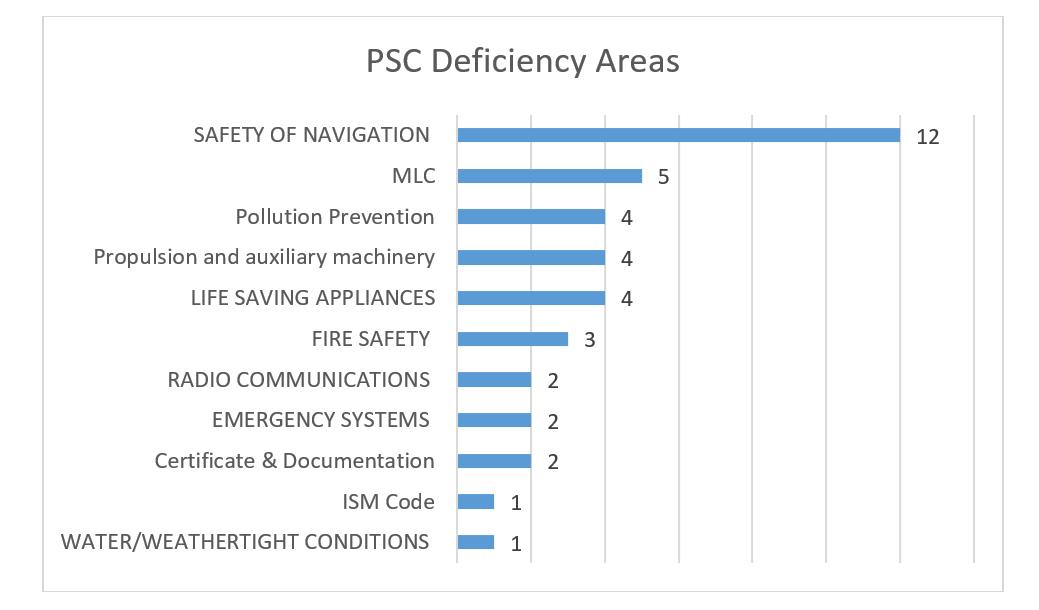

The breakdown of the Deficiency Areas (all deficiencies) that the ship found to be unsafe were:

Having a different look on the breakdown with operational groups for all deficiencies and categories in mind the list of the deficiency findings may be breakdown as follows:

Root Causes

Almost 90% of the ships being detained have NO (Zero) detentions in the 36 months prior to that detention. This is a strong and clear indication that all ships may be detained if they are not properly prepared. Research has provided evidence that the ships are being detained for the following key reasons

- Inadequate identification that the ship will be inspected: It is evident in this case by the end result

- Inadequate Preparation of the crew and the ship as a hardware: Numerous deficiencies in the areas where weekly inspections are due (FFA, Sfaety of Navigation, LSE) are a testimony to that

- Inadequate performance at the day of the PSC Inspection: The number of the overall findings are also a verification of that.

- Targeted ship or Manager: The Manager’s performance in port or country and ship’s previous history may lead the PSCO to a stricter inspection leading to detailed checking on practices on board.

Here all the above reasons have been observed leading to the obvious result.

POCRA preparation checklist

If the vessel had used the POCRA preparation checklist, the findings may have been resulted differently. The POCRA checklist in Nakhodka for General Cargo Ships in its full extent generates a specific checklist including 95 items analyzed in detail. This checklist includes all detainable items identified during inspection, and overall, 31 out of 40 findings during inspections. If the vessel had prepared properly the detention could have been avoided, as all detainable items have been already identified for the ship.

Lessons to be Learned

There are a number of lessons to be learned out of this case as follows:

- Ship’s and manager’s PSC history in specific area was problematic and identified from MoU

- The areas that a ship is exposed to a detailed inspection (as most PSC Officers are very competent to check) are LSA, Fire safety and Safety of Navigation.

- Ship had a very large number of procedural issues (safety of navigation, bridge procedures etc). This cannot go unnoticed from a PSC station that has a heavy finding track record.

- As PSC inspections aim to identify safety gaps onboard, having to many technical/procedural issues will possibly lead to detention.

Terminology Used

- DCS: Deficiency Codes Spread. Number of deficiency codes required to achieve the 100% of the Deficiency Codes in a Post. Alternatively partial indicators may be used such as DCS20, DCS50 or DCS80 te reach 20% 50% or 80% of total deficiencies in Port respectively

- Deficiency Profile – Detailed List of all PSC findings with an indication of the Deficiency Code (Detainable or Not)

- DER -Detention rate (% of inspections ended with detention)

- Detention Profile – Detailed List of all Detainable PSC findings with an indication of the Deficiency Code

- DPI – Deficiencies per Inspection, average

- Global Benchmark – The value of the KPI based on the Global statistics for same ship type and age

- L12M – Last 12 months period (rolling, at the date of the inspection)

- L36M – Last 36 months period (rolling, at the date of the inspection)

- POCRA – POrt Call Risk Assessment

- SIR – Ship Inspection Ratio – % of unique ships inspected vs unique ships called in port over the last 12 months

- UNLOCODE – Standardized UN code for each port/terminal, defined by UN. Please see UNLOCODE List

Did you subscribe to our Newsletter?

It’s Free! Click here to Subscribe!

Source: Safety4sea