- A self-organizing ecosystem (SOE) is a network of collaborating organizations that adapt to their environment.

- Shipping is a prime example of a SOE, involving port collaborations for centuries.

- Today, SOEs optimize routes, reduce costs, and manage disruptions.

- They are capital-creating mechanisms in free market economies, demonstrating successful production systems.

Successful collaboration by managing dependencies in the shipping ecosystem, highlights a Unctad news source.

A self-organizing ecosystem (SOE)

Written by Richard T. Watson, Mikael Lind, and Wolfgang Lehmacher, Article No. 110, [UNCTAD Transport and Trade Facilitation Newsletter N°99 – Third Quarter 2023]

A self-organizing ecosystem (SOE) is a collection of collaborating organizations that continually adapt to the forces they experience or anticipate.[1] Shipping is arguably the earliest large-scale SOE. Shippers relied on the collaboration of various parties in a port for berthing, mooring, cargo handling, furnishing supplies, crew, and so forth for thousands of years. Today, participants in the multimodal transport ecosystem seek coordination and alignment to optimize routes and shorten/avoid waiting and handling times at logistics nodes to improve service reliability, reduce costs and greenhouse gas (GHG) emissions, and better manage disruptions.

SOEs have increasingly become the capital-creating mechanisms of free market economies. They demonstrate that the fundamentals of any production system, division of labour and sequencing of events, can operate successfully as a set of collaborating organizations. In today’s complex market economy, organizations are largely free to connect digitally in vast networks of interrelationships. However, the economic viability of many members of an SOE is threatened when a dependency failure has critical upstream and downstream effects, as was witnessed when the Suez Canal was blocked by the Ever Given for six days in 2021.

The fundamental forms of dependencies

Successful collaboration requires managing dependencies across direct and indirect relationships. An initial step to their management requires recognizing the three fundamental forms of dependencies[2]

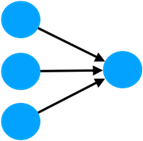

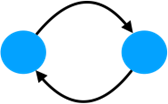

Table 1: The three fundamental forms of dependencies

| Type of dependency | Description | Visualization |

| Sequential | Success depends on a chain of single actors’ prior success. If one actor in a sequential chain fails, the performance of the following actors is jeopardized. | |

| Pooled | Success is reliant on a group of actors working independently in parallel to complete a project. If one fails to meet its delivery commitment, the task fails. |  |

| Reciprocal | Success is contingent on a group of actors working interdependently to complete a project. Projects fail if they don’t continually share information and react to each other’s progress. |  |

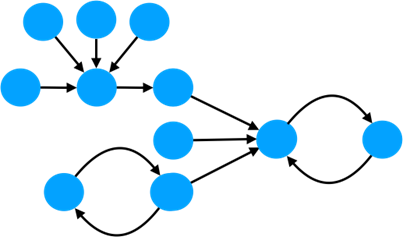

Complexity arises when (1) sequential chains are long, (2) pooled projects rely on many partners to deliver on budget, on time, and to specified functionality, and (3) partners in a reciprocal project fail to collaborate closely and continually. Complexity is further increased because many projects are hybrids of all three dependencies.

Figure 2: A project with multiple types of dependencies

Typical operational tasks and essential strategic projects reveal critical shipping ecosystem dependencies (Table 2). Notably, the most critical tasks and projects are hybrid.

Table 2: Shipping ecosystem dependencies

| Dependency/Focus | Operational | Strategic |

| Sequential | Supply chains in general | Project Sabre |

| Pooled | Tankers International VLCC Pool | Digital Container Shipping Association (DCSA) |

| Reciprocal | CMA CGM and TotalEnergies Port of Marseille Fos’ Ship-to-Containership LNG Bunkering Operation | Maersk / Egypt green energy partnership |

| Hybrid | Virtual Watch Tower Initiative (VWT) | Decarbonization of the maritime industry |

Dependencies in the shipping ecosystem

In today’s multimodal end-to-end supply chains, physical actions are strung together in regional or global transport networks. For example, the initial transport of goods to a port can be performed by truck, where the goods are unloaded, potentially stored, and later re-loaded onto a ship for transport to a destination port, possibly via one or more transit ports. At the destination port, the process is reversed. The goods can travel by barge, plane, train, truck, or a combination of those modes to the receiver of the goods.

All parties should align their plans for arrival, handling, and departure to avoid delays, encourage sustainable energy consumption, and maximize co-utilization of infrastructure. Effective collaboration is necessary to manage the multiple sequential dependencies between origin and destination.

Coordinating this sequential flow might also require management of pooled dependencies when some goods handling and movement are conducted simultaneously. For instance, when a supply chain network distributes components in complementary flows from multiple plants timely coordinated to one assembly plant to support just-in-time (JIT) production.

Managing reciprocal dependencies in an ecosystem is required when negotiations within the group influence the decisions of all players. Actions are co-determined to meet a joint goal. For example, in crises, such as the Covid-19 pandemic, critical players had to adjust jointly and rapidly their standard procedures to work around disruptions to deliver essential medical supplies.

Many experts are convinced that closer collaboration and alignment of action will make supply chains across the different modes more fluid and efficient. A dependency analysis can assist in anticipating collaborative challenges.

VWT – a case study for a hybrid collaboration

The goal of the virtual watch tower (VWT) is to improve coordination and collaboration to better deal with complex supply chain challenges. The initiative, which can be perceived as an internet of VWTs (VWTnet), is a cargo owner-driven, terminal-centric, distributed community and digital middleware for data sharing, analytics, and collaboration. A VWT must manage all types of dependencies to live up to its purpose.

Sequential dependencies: As VWTnet builds upon the physical network of supply chains, it requires the management of sequential dependencies. Coordination depends on data sharing. Beyond providing a digital data sharing infrastructure, a VWT uses a power of attorney to legitimately request required data from actors across supply chain networks.

Pooled dependencies: Private data shared by community members, enriched by relevant public data, helps to raise situational awareness. Thanks to powerful analytics, VWTnet can identify actual and potential network disruptions. Thus, forewarning factory management of disruptions to their JIT operations and production, which are pooled dependencies.

Reciprocal dependencies: Four examples illustrate how a VWT aids in managing reciprocal dependencies. First, the VWT allows actors to meet synchronously or asynchronously in a virtual situation room to collaboratively mitigate disruptions. Each party must understand how its actions influence other affected parties and adjust their actions to generate mutually acceptable outcomes. This gives rise to the second example, where a VWT manages reciprocal dependencies based on prior alternatives for mitigating disruptions. Thus, yesterday’s solutions form a repertoire of possible actions for managing disruptions today and tomorrow. Third, the community is reciprocally dependent on the continual expansion of the network. The network’s value and capabilities rely on the number and diversity of members. Such network effects often grow exponentially as membership expands linearly. Fourth, the tools and associated services a VWT provides reciprocally depend on identifying additional needs. As VWT is used, more requirements for extending its capabilities emerge.

The VWT is built on and for the management of dependencies. In Table 3 we have listed different forms of dependencies the VWT helps to manage.

Table 3: Managing dependencies with the Virtual Watch Tower

| Dependency/Focus | Operational |

| Sequential | Monitoring sequential transport operations along an end-to-end value chain |

| Pooled | Monitoring parallel flows of products from different locations scheduled for arrival at the same physical location at the same or coordinated times |

| Reciprocal |

|

New shifts in the dependencies landscape

Dependencies create complexity that companies often accept to gain operational efficiency and create effective strategic plays. Actors have substituted collaborative management of dependencies for command and control. We believe continually re-examining dependencies is essential for sustained profitability in today’s fast and volatile business context.

The world of supply chains is shifting. For example, many enterprises now recognize that changing political circumstances have magnified some dependencies to the point where there are more profitable alternatives by restructuring relationships, such as regionalizing or localizing parts of production. Adjusting their supply chain networks will create new dependencies that need to be structured, understood, and managed.

Reciprocal dependencies are increasing. Primarily driven by today’s unprecedented level of SOE complexity, the shifting geopolitical context, fourth industrial revolution technologies, and the environmental and climate challenges with their consequences for supply chain networks and humanity. This increases the need for strong dependencies management capabilities.

The essence of dependencies management

Independent of the type of dependency, the strive is to reduce dependency complexity to improve collaboration and reduce transaction costs. This requires synchronization of dependencies. In shipping, this means, for example, that arrival and departure times are shared when set and when they change. Viewing supply chain dependencies holistically helps participants reduce complexity, for instance, by instituting rules on how to act in different contingencies, such as a significant disruption or an oil leakage causing an environmental crisis.

Digital solutions, such as the VWT, for continually monitoring dependencies across supply chain networks and identifying emerging threats and opportunities are essential for high-performance and sustainable shipping. Operational dependencies across supply chain networks follow the chain of custody, which is the chronological documentation along a supply chain, leveraged by the VWTnet to keep cargo owners and other parties informed about the progress of their goods and facilitates collaboration, such as analytics and fact-based discussions in virtual situation rooms.

Today’s digital tools for improving collaboration permit managing dependencies at scale. Awareness about the dependencies across a network, such as tools like the power of attorney, helps to manage supply chains more tightly. At the societal level, we also need to consider nature/climate and social dependencies.

Effective partnerships are configured based on dependencies. Selecting a partner based on its reliability to meet associated dependencies is critical. The VWTnet is a way of better understanding and managing supply chain dependencies.

Identifying the future

The global financial crisis of 2007-09 revealed the complexity of the dependencies existing within the financial industry. Firm A’s dependency on firm B could not be universally tracked. As a result, the repercussions of a failure of one financial entity could not be quickly determined. The economic effects were contagious because no global standard for identifying vital financial linkages existed. Economic resiliency across all industries requires ensuring that when parties fail or default on their obligations, the ripples of such shocks do not cause a breakdown in one or more regions or industries.

A Global Legal Entity Identifier (LEI) was introduced as a unique identification of every financial entity so critical dependencies could be identified before a crisis.[3] Implementing the LEI was essential to raising the financial resiliency of the world’s major economies.

The LEI can also provide a foundation for increasing the global shipping industry’s resiliency. Knowing your physical and digital exposures is essential to building a more resilient organization in a hyper-dependent society showing signs of friction, fragmentation, and decoupling.

Thus, we advocate that the shipping industry examine the adoption of LEI and augment it with data essential to predicting and handling dependency failures following the blueprint of the financial services industry. The unique vessel identifier (UVI) could be directly linked to the owning entity’s LEI. Similarly, the industry should consider uniquely identifying all key shipping infrastructure, like a crane. When there is a failure, all affected elements should be quickly identifiable to determine potential ripple effects and initiate corrective action.

Conclusions

Executives need a framework for managing dependencies. Those operating in industries subject to frequent disruptions, such as logistics, need tools to monitor and react to dependency fluctuations. The VWT case illustrates how various types of dependencies can be managed to improve collaboration across a diverse range of actors involved in global supply and demand networks. We promote VWTnet and the adoption of a global resource identification system to enable accurate real-time assessment of dependencies to fare better in future challenging situations.

[1] Watson, R. T., Lind, M., Delmeire, N., & Lieaa, F. (2020). Shipping: A Self-Organizing Ecosystem. In M. Lind, M. P. Michaelides, R. Ward, & R. T. Watson (Eds.), Maritime Informatics. Springer.

[2] Thompson, J. D. (1967). Organizations in action; social science bases of administrative theory. McGraw-Hill.

[3] Chan, K. K., & Milne, A. (2013). The global legal entity identifier system: Will it deliver? Available at SSRN 2325889.

Contact the authors:

- Richard T. Watson | Digital Frontier Partners | richard.watson@digitalfrontierpartners.com

- Mikael Lind | Research Institutes of Sweden (RISE) & Chalmers University of Technology | Mikael.Lind@ri.se

- Wolfgang Lehmacher | Anchor Group & Topan AG | w.lehmacher@gmail.com

Disclaimer

Did you subscribe to our daily newsletter?

It’s Free! Click here to Subscribe

Source : Unctad