IMCA reports an incident where unplanned movement of equipment leads to severe injuries.

What happened?

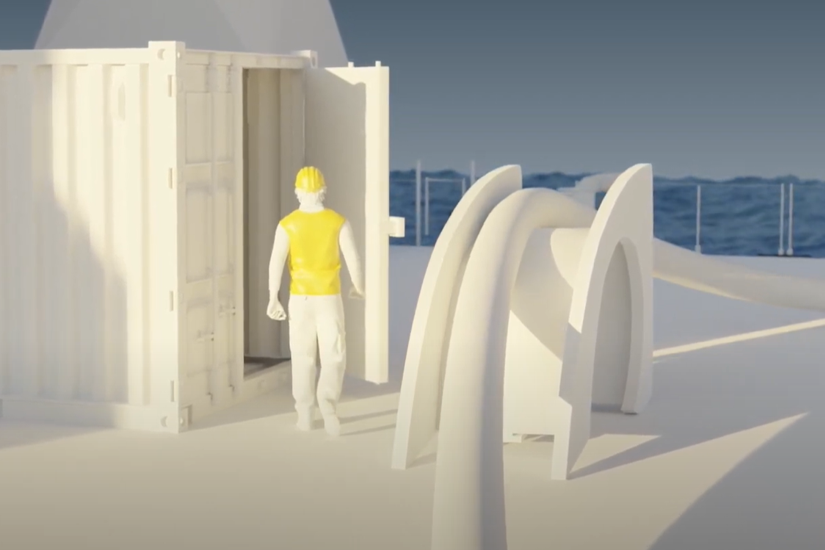

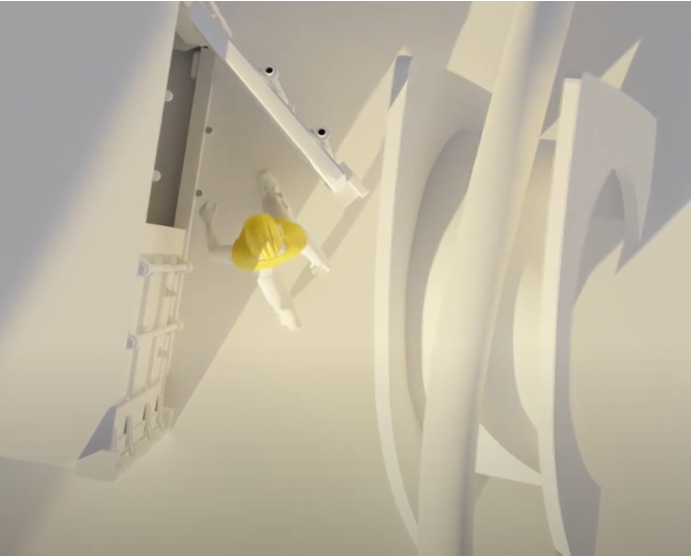

A mechanic was caught in the door of a freight container by a tipped-over hose saddle weighing 3 tonnes. The incident occurred when a team was performing maintenance works to a hydraulic spread on deck. A mechanic, who was not involved with these works, passed by the hose saddle, and entered a nearby container. At that moment the hydraulic hoses moved, causing the hydraulic saddle to tip over towards the container door, trapping the mechanic in between the container door and the frame. He sustained severe injuries for which he underwent surgery, and will be off work for more than 6 months.

What went right

Emergency response was initiated properly and in a timely manner and the injured person rescued. First Aid was given on site until the person could be evacuated to a nearby hospital.

What went wrong

Multiple things went wrong leading up to the incident:

- The hose saddle was not secured to the deck and due to its shape has a high centre of gravity, making it unstable.

- Because of the maintenance activities, the hose saddle was repositioned on deck, without a Management of Change (MoC) procedure being implemented.

- People working in the area were informed of the pressure tests on the hoses, but the mechanic was not there at that briefing. No Permit to Work was requested, nor was the area barricaded.

What were the causes of the incident

The following causes were identified:

- No “Safety By Design”: the hose saddle was top-heavy and was not sea fastened.

- No risk assessment or management of change was done before repositioning the hose saddle.

- There was no proper risk management of ongoing (simultaneous) activities, for example, Permit to Work, barricading of the area, and thorough communications to all stakeholders.

Lessons and actions

- Incorporate “Safety by design” for all tools and equipment (including the importance of stability).

- When there is a deviation from the planned work, a Management of Change procedure should take place.

- Proper implementation of the Permit to Work system as and when required.

- All people involved in the job and in the work, area should take part in the toolbox meeting before starting work.

IMCA member took the following actions:

- Assessed the stability of all deck equipment.

- Sea-fastened all (unstable) deck equipment, also equipment which was in temporary locations.

- Reinforced the importance of procedural safety barriers such as the Management of Change process, last-minute risk assessment, and the Permit to Work system.

- Worked to improve safety coordination between all parties, including subcontractors.

Did you subscribe to our daily newsletter?

It’s Free! Click here to Subscribe!

Source: IMCA